The problem with salt: crucial for winter safety, but what is the cost?

By Pam Strong, Lake Simcoe Region Conservation Authority

Canadian winters present many challenges for parking lot and property managers across the country, with their mix of snow, sleet, and freezing rain. The use of snowplows and the application of sand is one of the only options for colder climate areas in Canada and will generally provide the traction needed for safe conditions. In more temperate areas, however, the application of a de-icing agent is often required alongside plowing. These are typically some of the country’s more highly populated areas, making proper maintenance crucial due to the higher traffic volumes. Winter maintenance is a challenge in these areas, where temperatures often hover around the freezing mark and freeze-thaw cycles are common. However, it is in these conditions where the use of road salt (i.e. sodium chloride) has become the common, practice. As its use has become increasingly widespread over the past several years, with approximately seven million tonnes applied annually in Canada, we have also come to realize that its use comes with several significant environmental and financial consequences.

Road salt has been in use as a de-icer since the late 1940s, and it has become the most used tool in the winter maintenance toolbox. It is relatively inexpensive, generally easy to access, easy to store and use, and it is highly effective at melting snow and ice, at temperatures down to -9° Celsius. These characteristics have led to its widespread use for road maintenance, and for private residences and parking lots of all types. In 2004, Environment Canada introduced a Code of Practice for the Environmental Management of Road Salts, for use by road maintenance agencies. Since that time, these agencies have been making efforts to refine their winter maintenance practices and reduce the amount of salt applied where possible. Parking lot managers are in the difficult position of balancing public and customer expectations of bare pavement regardless of weather conditions, fear of lawsuits, increasing insurance premiums, and some uncertainty about how salt and other de-icers work, and without a similar Code to provide guidance. These all lead to a tendency to err on the side of caution, and just “put down a little more to be safe,” and a little more often turns out to be a lot more, regardless of whether it’s needed.

The issues with salt use

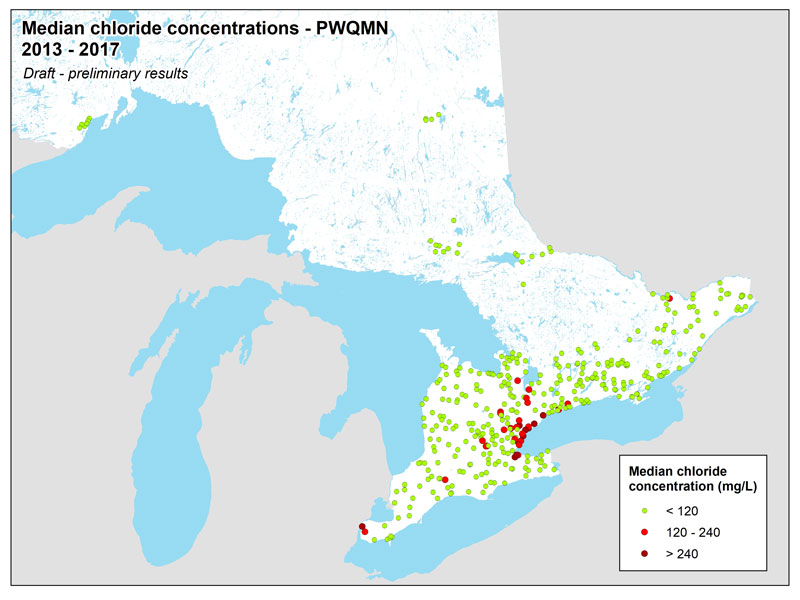

While salt has typically been seen as a safe substance that dissolves and ‘disappears’ when it rains or the snow melts, this is unfortunately not the case. Once it has dissolved, it is extremely mobile, and it is almost impossible to remove. Increasing levels of chloride, a component of salt, have been increasing in lakes, streams, wetlands, and other waterbodies, as well as in groundwater, across Canada and the northeastern United States (Map shows where this is occurring in the urban areas of Ontario). Levels of salt in some freshwater streams regularly see levels as high as sea water, and high concentrations often persist year-round. This is harmful to our native aquatic plants and animals and can cause changes in the functions of these natural systems, as well as shifts in communities to species that are better able to tolerate adverse conditions. A visible example of these impacts is the damage and death of vegetation growing near roadways, where it can be reached by road spray and runoff. In addition, due to its high mobility once dissolved in water, salt can reach groundwater resources, potentially affecting drinking water sources in impacted areas.

Map caption: The results of monitoring chloride concentrations in Ontario streams since the early 1970s (Source – Government of Ontario, Water Quality in Ontario, 2011 – data updated to 2017)

In addition to the environmental impacts, salt causes significant damages to built infrastructure. It has been linked to the premature deterioration of bridges and other road infrastructure; potholes and cracking of concrete; damage to masonry; corrosion of metal elements such as railings, cart corrals, and doorways; and damage to flooring. Annual costs for repair and replacement of this infrastructure can be substantial and will increase with the application of larger volumes of salt. Considering the staggering amount of salt applied in Canada every year, repair and replacement costs could total in the billions. While repairs to roads and bridges would certainly be on the more costly end of these repairs, the amount that parking lot owners need to spend is still significant. Many parking lot owners find that certain items, such as landscaping features often need to be replaced on an annual basis. Combine these costs with the cost of the extra salt that’s being applied, as well as those of repairing heaving walkways, corroded metal infrastructure, and replacing flooring, and the ‘relatively inexpensive’ cost of using road salt to maintain safe surfaces doesn’t seem quite so low. The good news is that the proper use of salt can help to reduce these costs.

Challenges for winter maintenance in parking lots

As noted above, parking lot managers are subject to a number of winter maintenance challenges, many of which differ from those faced by roads managers. Of course, the priority is maintaining the safety of parking lot users. This is most commonly accomplished through plowing the lot and applying a de-icing material to remove residual ice and/or snow. This has been sufficient in the past; however, in recent years there has been an ever-increasing public view in many areas that parking lots and walkways should be completely clear of snow and ice, regardless of the weather conditions. This has led to a prevalent belief that contractors and parking lot managers are at high risk of liability. A study commissioned by LSRCA indicates that the risk of legal liability should be low where contractors and parking lot managers are being reasonable in the management of their properties, and carefully document their work. However, despite this seemingly low risk of legal liability, the financial implications can be substantial. This is because slip and fall lawsuits are often settled by insurance companies before reaching the courts, preventing defendants from being able to exercise their due diligence defence. Because of this, insurance premiums and deductibles have increased significantly, and there are fewer insurers that will cover winter maintenance activities. This is causing contractors and property managers to avoid liability any way they can, and the application of large volumes of salt, has become the go-to solution for ensuring that surfaces are clear of snow and ice. However, this does not necessarily make conditions safer, and we now know that this excess salt causes a host of other issues.

During the winters of 2018 and 2019, the Lake Simcoe Region Conservation Authority (LSRCA) in Ontario measured the friction found in various conditions at commercial parking lots around Newmarket and Aurora, in the Greater Toronto Area. Their findings showed that when the snow was removed from the surface and it was treated with an appropriate amount of salt, in the range of 58 g/m2 (13 lb/1000 ft2) the surface was left with no residual salt, free of ice and snow, with good traction. On the other hand, the application of salt at higher rates left residual salt grains, which actually reduced traction. This research showed that where the goal is safe surfaces for parking lot users, the over-application of salt is not the answer.

Improving our practices

Several public agencies, trade groups, and academics have been working on solutions that will maintain safety in parking lots while reducing salt use. This work varies widely and offers a number of options for tackling this issue. Here are some highlights of work being undertaken in southern Ontario:

n Best Practices Guidelines: While there is not yet an officially agreed upon Code of Practice, or set of guidelines, there are several examples of best practices guidelines that can assist parking lot managers. The Transportation Association of Canada has developed winter maintenance practice guidelines for many situations and includes a section on parking lot maintenance. In Ontario, the provincial government developed guidelines in 2011. More recently, Marsh Risk Consulting, in partnership with Landscape Ontario and the Canadian Nursery Landscape Association, developed a set of guidelines from a risk management perspective. It is the general hope that these guidelines could be used in a due diligence defence – if a contractor or site manager could prove that they were following a set of guidelines (e.g. through documentation of practices being used on the site), this should support their defence in a slip and fall case. It is hoped that at some point, there will be an “official” set of guidelines that parking lot managers can use universally to defend themselves in these cases.

n Salt Management Plans: while these are typically considered as part of best practices, they are worth noting here. It is critical that the usage patterns of each site be considered individually to tailor winter maintenance practices. These plans provide clear maintenance expectations, which should be agreed upon between the parking lot manager and the contractor. Items that can be considered through the development of a site plan include differing salt application rates for different areas, depending on use; seasonal closures of parking lot sections or walkways that aren’t well used; areas where alternative materials or practices are to be used (i.e. on permeable pavement); and signage and barriers to be used for snow storage and closed areas.

n Alternative Practices and Materials: plowing of surfaces followed by the application of a chemical de-icer such as salt are the typical practices followed in parking lots, there are alternative practices and materials that can be used in these areas. These include the use of brine, pre-wetting as the salt is applied, and the use of salt alternatives such as beet juice and treated salt.

n Procurement Guidelines: guidelines have been developed to assist parking lot managers in hiring contractors that are capable of undertaking winter maintenance to ensure the safety of users while using best practices and minimizing the amount of salt used. A good example of these guidelines is available through the Sustainable Technologies Evaluation Program.

n Training and Certification: one way to ensure that best practices are being used on a parking lot is to use certified contractors. One such certification available in Canada is through the Smart About Salt Council (link). Certification of both contractors and facilities is available through their programs.

n Parking Lot Design Guidelines to Promote Salt Reduction: these guidelines, which were developed by the LSRCA in 2017, contain measures that can be used in the parking lot design phase that will help to reduce the amount of salt that needs to applied. These guidelines include consideration of four factors of parking lot design: effective grading and stormwater collection, snow pile storage location, sidewalk design and pedestrian flow, and the use of landscaping features. These guidelines will be discussed in detail in a future Parker article.

Protecting parking lot users, freshwater resources, and the bottom line

There are many resources available to winter maintenance contractors and property managers that can lessen the impact of winter maintenance activities while ensuring the safety of parking lot users is maintained. The implementation of even some of these practices can go a long way toward limiting the exposure of contractors and parking lot owners and managers to liability, keeping their insurance costs lower. Added benefits include a reduction in the materials costs for salt, as well as decreasing annual winter maintenance and repair costs and prolonging the life of built infrastructure. This can all be accomplished while protecting our freshwater resources for generations to come. ν

You can find more information on this issue on our website’s salt page at https://www.lsrca.on.ca/watershed-health/salt

Feature photo caption: A damaged sidewalk in a southern Ontario parking lot. Salt will exacerbate the effects of the freeze-thaw cycle, often causing significant damage to concrete and asphalt.

Good Day,

is it permissible to use blue salt during the canadian winter to combat ice in the outdoor parking spaces of buildings when there are indoor parking spaces located belo, or is not permitted?

What are the best methods or materials to use to combat ice ?

thank you in advance for your prompt action & cooperation.

Regards,

Georges