North American Precast Concrete Industry Issues Environmental Product Declarations

By Ariane Sabourin and Brian J. Hall

In the context of environmental impact, the choice of construction products and building systems is significant, and is continuing to grow in importance. In 2013, the building and transportation sectors combined for an estimated 256 Mt or 35% of the total greenhouse gas emissions in Canada. Emission intensive industries accounted for an estimated 76Mt, or 11% (Globe and Mail, January 23, 2016). Selecting a product, brand, or building system will determine the resources used, pollution created, carbon dioxide emitted and waste generated – preference impacts more than just style, function, performance and cost.

Sustainability and environmental performance has been a priority for the Canadian Precast/Prestressed Concrete Institute (CPCI) and its members since the inception of its Sustainability Committee in 2007. CPCI’s sustainability mission is to encourage the development of environmentally sound and sustainable practices in the design, procurement, production, transportation, and erection of precast concrete. As the national voice of the precast concrete industry, CPCI leads and advocates the precast concrete industry’s contribution to a sustainable built environment and green building practices. We collaborate and partner with other organizations to research and develop sustainable design innovations and building system solutions.

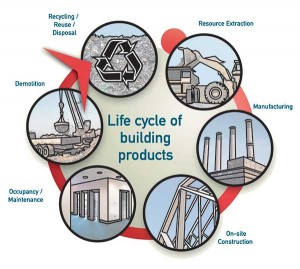

In 2008, CPCI commissioned Morrison Hershfield and the Athena Sustainable Materials Institute (ASMI) to develop an industry specific life cycle assessment (LCA). The final study entitled Life Cycle Assessment of Precast Concrete Commercial Buildings: Cradle-to-grave was published in 2012. It provides an assessment of precast concrete’s environmental performance in the context of building construction, use, and end of life from extraction, production and transport of raw materials, through to the manufacturing and transport of the product to the project site, the assembly on site, customer use, occupancy, and maintenance of the structure and finally, the end of life reuse, removal or disposal of the product. In other words, it tells the entire story, revealing the environmental impacts at every phase and helps to clarify where the biggest improvements can be made – something the precast concrete industry takes very seriously.

In 2012, we also introduced the CPCI Sustainable Plant Program, an environmental tracking program designed to encourage continuous improvement and compliance to environmental and sustainability regulations and standards. Through the program, CPCI member plants track their materials, transportation, energy, and waste generation and diversion at the manufacturing level, to benchmark three environmental impacts (CO2eq, Total Primary Energy and Water use). The program has succeeded to create a culture of sustainability within the precast concrete industry; one that we expect will filter through the entire construction industry.

In 2014, the CPCI sustainable plant program was adopted by the National Precast Concrete Association (NPCA) and the Precast/Prestressed Concrete Institute (PCI), and was renamed the North American Precast Concrete Sustainable Plant Program (NAPCSPP). More than 100 precast manufacturing plants across North American now participate in this important initiative, each reporting to their respective associations. For the past three and a half years, CPCI has published a quarterly industry average report of the Canadian reporting plants, which can be found on CPCI’s website, at www.sustainableprecast.ca.

As part of the evolution towards a more sustainable industry, in 2015, CPCI partnered with NPCA and PCI to develop Environmental Product Declarations (EPDs) in three key precast concrete product categories: Architectural and Insulated Wall Panels, Structural Precast Concrete Products and Underground Precast Concrete Products. An EPD is a standardized, internationally recognized, comprehensive tool for providing information on a product’s environmental impact. Information in the EPD documents is based on an ISO-compliant Life Cycle Assessment (LCA) and verified by a third-party. The detailed analysis considers all processes in the manufacturing of a product, including raw material and energy extraction, preliminary production and the manufacture of end products.

Calgary International Airport Parkade – Mitigation of the urban heat island effect (UHI) was accomplished through the use of lighter-colored surfaces in the parkade, which reflect more sunlight and absorb less heat.

Parking Garage

at the Halifax International Airport – The basket weave effect on the load bearing precast wall and the use of long span double tees permitted more natural light, which reduced the energy requirements during the day.

The precast concrete EPDs were independently prepared by Athena Sustainable Materials Institute in accordance with ISO 14025 and ISO 21930; the Product Category Rules for Preparing an Environmental Product Declaration for Precast Concrete (UN CPC 3755), March 2015; and ASTM international’s EPD program operator rules. They were also independently verified by ASTM International (in accordance with ISO 14025) and by Industrial Ecology Consultants (in accordance with ISO 14025 and the Product Category Rules). To download copies of the precast concrete EPDs, please visit www.sustainableprecast.ca.

The precast concrete EPDs allow architects, engineers, building owners, and other specifiers to better understand the environmental impacts of precast products and inform them on crucial decisions around the selection of building materials for their projects. In support of this, LEED™ v4 has incorporated a new credit for EPDs that have been third-party verified by an approved program operator. For more information on LEED™ credits, visit www.usgbc.org and www.cagbc.org.

CPCI, NPCA and PCI are the leading technical resources for the precast prestressed concrete industry in North America. From this body of knowledge, building codes, design guides, educational programs, certification, sustainability programs, and new research ideas are derived. This joint industry initiative develops, maintains, and disseminates the knowledge and information necessary for designing, fabricating, and constructing sustainable and resilient precast concrete structures.

Full Product Transparency is about providing a complete picture of the environmental impact of a product throughout its life. The North American precast concrete industry is proud of the steps we have taken thus far to encourage a sustainable built environment, and we strive to continue to make improvements that will benefit the transportation and building sectors.

Hello Ariane and Brian – The article was very insighltful. Sustainability should be the priority for all industries across globe.Precast Concrete market is blooming worldwide. One of the research report by DecisionDatabases.com expects the market to grow to USD 58.8 billion by 2022.

Your article helped me in the college project. Thanks.